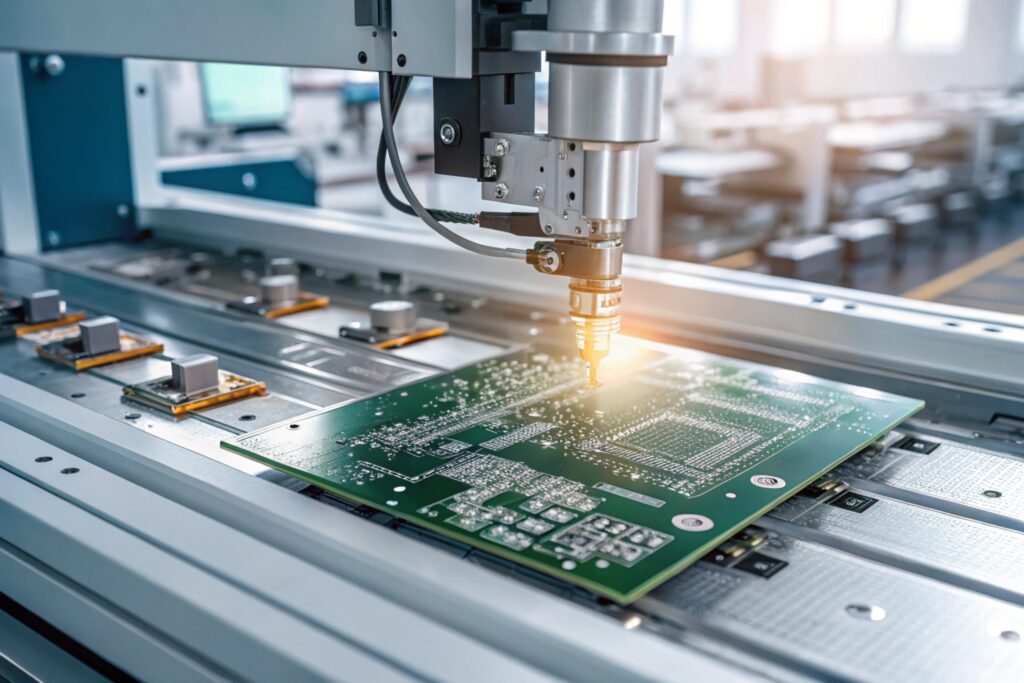

Solder paste printing technology is an essential method in the modern electronics manufacturing industry. It offers several benefits that streamline production and ensure high-quality results. But what exactly are these unique advantages?

Solder paste printing1 offers precision, consistency, and cost efficiency. It is crucial for high-speed, high-volume PCB production[^2]. The key advantage is its ability to consistently apply fine amounts of solder paste, enhancing the reliability of solder joints and improving overall production efficiency.

As we explore further, we'll uncover why solder paste printing is a go-to method in many electronic assembly lines.

[Table of contents]

What are the advantages of solder paste?

Opening paragraph for h2: When it comes to soldering, understanding the specific benefits of solder paste is crucial for ensuring quality results. So, what exactly does solder paste bring to the table?

Solder paste1 enables precise, uniform deposition of solder onto PCBs[^2], ensuring reliability and quality in every solder joint. It also reduces defects such as bridging[^3], enhancing the integrity of the final product.

Dive Deeper sections for h2:

Increased Precision

Solder paste allows for the accurate application of solder to tiny pads and components on a PCB. This precision reduces the risk of errors and defects in the assembly process.

Enhanced Quality Control

By using solder paste, manufacturers can easily achieve consistent results, which is vital for the high standards of modern electronic products.

Cost-Effective Manufacturing

Using solder paste also helps reduce costs associated with rework and scrap. Its application is less wasteful compared to older methods, which helps improve overall cost-effectiveness.

What are the advantages and disadvantages of soldering?

Opening paragraph for h2: Soldering is a critical process in PCB assembly, but it comes with both benefits and drawbacks. Let's examine both sides.

Soldering offers strong electrical connections, but it can also introduce challenges like potential for thermal damage and component stress. Understanding these pros and cons helps manufacturers make informed decisions.

Dive Deeper sections for h2:

Advantages of Soldering

Soldering creates a durable bond between components, providing strong electrical and mechanical connections. It's a time-tested method that has been used in electronics for decades.

Disadvantages of Soldering

Soldering can expose components to excessive heat, potentially damaging sensitive parts. Furthermore, solder joints may weaken over time, requiring additional maintenance.

What is solder paste printing?

Opening paragraph for h2: Solder paste printing is a crucial step in the SMT (Surface Mount Technology) process. But how does it actually work, and why is it so essential?

Solder paste printing is the process of applying solder paste onto a PCB before component placement. It ensures uniform paste distribution, which is critical for successful soldering.

Dive Deeper sections for h2:

How it Works

A stencil is typically used to apply solder paste in precise locations. The process ensures that the correct amount of paste is placed on each pad, facilitating proper soldering during reflow.

Benefits of Solder Paste Printing

The main benefit is high precision, allowing for the accurate placement of components. This is especially vital for small and complex PCBs.

How It Affects the Final Product

Proper solder paste printing ensures that the solder joints formed during reflow are strong and reliable, minimizing defects like cold joints or bridging.

What are the characteristics of solder paste?

Opening paragraph for h2: Understanding the unique properties of solder paste helps optimize its use in electronic manufacturing. But what are these key characteristics?

Solder paste is a mixture of tiny solder spheres, flux, and a vehicle to help the paste flow. Its properties determine its performance in the soldering process, making it an essential material for high-quality PCBs.

Dive Deeper sections for h2:

Key Ingredients

Solder paste typically consists of lead-based or lead-free solder alloy particles, flux, and a binder. The composition affects the flow, wetting, and adhesion during reflow soldering.

Flow and Viscosity

The paste's viscosity is crucial for achieving optimal paste transfer. If the paste is too thick, it may not transfer correctly. If it's too thin, it can result in excessive solder or bridging.

Shelf Life

Solder paste has a limited shelf life and requires proper storage to maintain its properties. Once opened, its performance can degrade quickly, which is why handling and usage conditions are important.

Conclusion

Solder paste printing technology provides a precise and efficient solution for modern electronics manufacturing, offering both technical and economic advantages. By understanding the unique benefits and characteristics of solder paste, companies can improve quality while reducing costs.

1.png)