I see damaged mezzanine connectors1 slowing our production. This problem wastes time and resources. I feel frustrated by repeated failures. But I believe solder paste jetting[^2] can fix these connectors quickly and accurately.

Solder paste jetting repairs mezzanine connectors[^3] by applying precise, controlled paste deposits, allowing efficient rework and improved reliability.

I remember when my older methods failed. I tried basic soldering techniques[^4], but they never matched the accuracy I needed. I want to show you how solder paste jetting[^2] changes this situation.

[Table of contents]

- How solder a FPC connector?

- How do you repair solder?

- What is the jetting process of solder?

- How do you solder a cup connector?

- Conclusion

- About My Business

- About My Typical Customers

How solder a FPC connector?

I remember the first time I tried to solder a Flexible Printed Circuit (FPC) connector. It was delicate, and one slip would ruin the pad. I needed a clear approach.

I can solder an FPC connector by aligning it gently, applying measured solder paste, and carefully reflowing to create stable contacts.

I recall when my team struggled with thin connectors. After learning a step-by-step method, we achieved perfect bonds.

Preparing the FPC Connection

I start by cleaning the FPC pads. I ensure no debris remains. I use a gentle brush or compressed air. This prevents contamination and improves adhesion.

- Cleanliness: Essential for secure joints.

- Surface Preparation: Smooth, flat pads ensure better paste bonding.

Aligning and Depositing Solder

I use solder paste jetting to place tiny amounts of solder exactly where needed. I align the connector pins over the pads. I make small corrections until perfect.

Snippet paragraph for H2: FPC connector soldering works best when I position the connector precisely, apply correct solder amounts, and gently heat until the solder flows.

I remember when my partner tried manual soldering and caused bridging. Now, with solder paste jetting, I avoid messy connections.

Fine Pitch Challenges

Tiny pin spacing demands accuracy. I learned to zoom in with a microscope. I rely on controlled jetting to avoid excess paste.

Table: Common Issues and Solutions in FPC Soldering

| Issue | Cause | Solution |

|---|---|---|

| Solder Bridges | Excess paste | Reduce deposit volume |

| Weak Joints | Insufficient paste | Apply slightly more paste |

| Misalignment | Poor positioning | Use magnification, alignment jig |

Ensuring Secure Bonds

After depositing paste, I apply controlled heat. The solder melts and bonds the connector. This creates a reliable connection. The result is a stable FPC interface that supports signals without failure.

How do you repair solder?

Sometimes solder joints fail. Maybe they crack under stress. Maybe they form bridges. I need a method to repair them quickly without replacing the entire board.

I repair solder by removing damaged portions, cleaning the area, and reapplying fresh solder paste with precise jetting.

I remember when I tried to fix a cracked joint by adding solder manually. That caused lumps and instability. Now I prefer controlled methods.

Identifying the Issue

First, I spot the problem. I inspect joints with a magnifying tool. I look for cracks, voids, or cold joints. I note exactly where the defect is.

Common Defects in Solder Joints

- Cracks: Occur due to mechanical stress.

- Cold Joints: Result from insufficient heat.

- Bridges: Happen when solder flows between unintended pads.

Removing Defects

I use a solder wick or desoldering tool to remove old solder. I ensure a clean pad. I avoid damaging the board. I remain patient.

Snippet paragraph for H2: To fix solder, I identify the flaw, remove old solder, and add new paste with a jetting system, ensuring a stable, clean joint.

I remember when I rushed and pulled pads off. Now I go slow and steady.

Step-by-Step Removal Guide

- Apply Flux: Helps old solder flow.

- Use Wick or Pump: Gently remove solder.

- Clean the Pad: No residue should remain.

Reapplying Paste

With the area cleaned, I jet fresh solder paste precisely. I place just enough for a solid bond. After heating, the joint looks like new. It restores functionality and reliability.

What is the jetting process of solder?

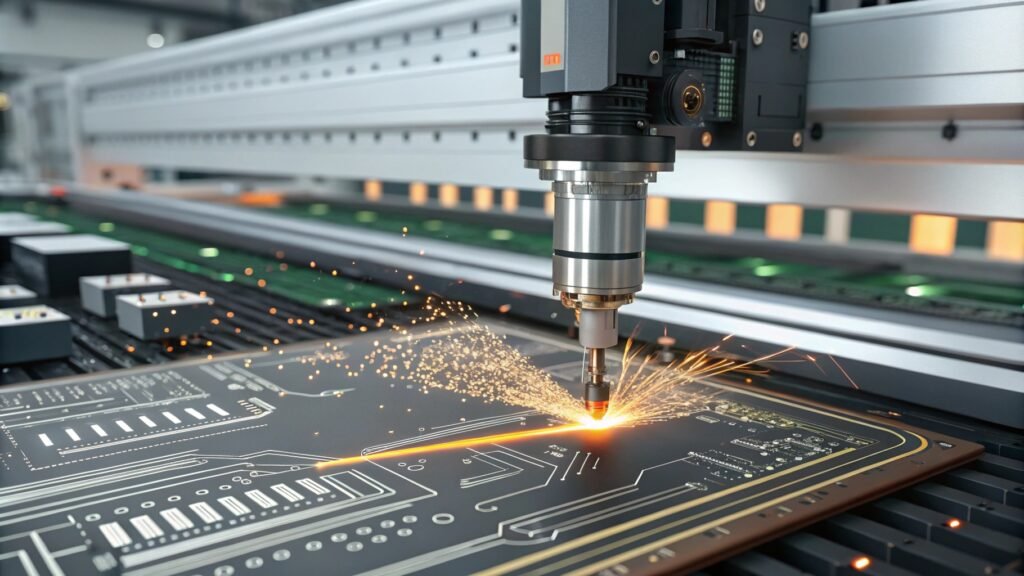

I know solder paste jetting sounds complex. It involves pumping controlled droplets of solder paste onto specific locations. I rely on specialized equipment.

The jetting process involves using a piezoelectric valve to deposit precise solder droplets without contact, ensuring accurate placement and minimal waste.

I remember when I first saw a jetting system at an expo. It impressed me with speed and precision.

Basic Principles of Jetting

Solder paste jetting uses a pressurized chamber and a nozzle. The valve opens briefly, ejecting a tiny droplet. I control droplet size by adjusting parameters.

Key Parameters in Jetting

- Valve Frequency: Determines how many drops per second.

- Droplet Volume: Adjusted by valve timing.

- Nozzle Diameter: Affects droplet size.

Equipment and Setup

I use a jet valve mounted over a PCB. The machine reads a program generated from Gerber data. It knows where to place each droplet. I no longer need stencils or guesswork.

Snippet paragraph for H2: The solder jetting process uses automated equipment to place precise solder paste droplets, guided by software, ensuring consistent and accurate results.

I recall when I hand-applied solder paste with a syringe. It was tedious and prone to errors. Now I trust the machine.

Detailed Look at Jetting Components

| Component | Function |

|---|---|

| Piezoelectric Valve | Controls droplet release timing and volume |

| Nozzle | Shapes the droplet as it exits the valve |

| Controller Software | Translates board design into instructions |

Process Optimization

I tweak valve parameters and adjust temperatures. Different boards need different settings. Over time, I learn the best configurations. I get repeatable outcomes and reduce waste.

How do you solder a cup connector?

Cup connectors differ from mezzanine or FPC types. They have small cups to hold solder. Jetting helps place the right amount inside the cup. I gain a neat and stable joint.

I solder a cup connector by depositing solder paste inside its cups, then heating to create a reliable joint that secures wires or leads.

I recall when I tried manual soldering and spilled solder outside the cup. Jetting eliminates that issue.

Understanding Cup Connectors

Cup connectors are hollow. I place a wire end or component lead inside. I want solder to fill the space evenly. Jetting ensures a perfect fit.

Challenges with Cup Connectors

- Overfilling Cups: Causes spillage.

- Underfilling Cups: Weak joints.

- Misalignment: Hard to position wire or component perfectly.

Applying Solder Paste Accurately

I set the jetting system to deposit a measured amount of paste into each cup. I ensure the wire end is in place. After heating, the solder flows around the wire, holding it firmly.

Snippet paragraph for H2: To solder a cup connector, I precisely deposit solder paste into the cup, insert the wire, and reflow, forming a stable, conductive bond.

I remember when I had trouble with uneven joints. Now each joint is uniform and strong.

Step-by-Step Procedure

- Clean Connector: Remove debris.

- Align Wire or Lead: Position it in the cup.

- Jet Solder Paste: Use calibrated settings.

- Reflow: Heat until solder solidifies.

Achieving Reliable Joints

After reflow, I test the joint by applying gentle tension. It must hold firmly. A good joint shows no cracks. It ensures long-term reliability.

Table: Common Cup Connector Issues and Solutions

| Issue | Cause | Solution |

|---|---|---|

| Weak Grip | Insufficient solder | Increase paste volume slightly |

| Solder Overflow | Too much solder | Reduce jetting parameters |

| Poor Conduction | Contamination | Ensure surfaces are clean |

Conclusion

Solder paste jetting transforms how I repair mezzanine connectors and handle various connector types. I gain precision, speed, and reliability, making my rework process more efficient.

About My Business

My Name: Jony Yue

My Email: qiangyue@solderforce.com

Link to My Website: www.solderforce.com

Brand Name: SolderForce

Country: China

Products: Solder Paste Dispenser

Business Model: B2B

Status: I developed a solder paste piezoelectric jet valve. I can customize product specifications to meet personal needs. I support Gerber import to generate instructions with no manual input. I export mainly to India, North America, South Korea, Russia, and Vietnam.

Possible Client Identity: SMT factory procurement, electronics industry, photovoltaic industry, and electronic DIY enthusiasts.

Product Features: Top quality, customizable logo, rare style.

Promotion Channels: Alibaba, exhibitions.

About My Typical Customers

Name: Mark Chen

Country: India

Age: 40 years old

Characteristics: Mark handles company procurement. He must meet process requirements. He has no direct decision power.

Primary Purchase: Solder paste jetting equipment.

Buying Preference: Needs process compliance, values quality, still wants good prices.

Status: Company owner and buyer.

Main Sourcing Locations: China.

Profit Model: Uses automation equipment to produce and sell products.

How to Find Suppliers: Tradeshows, Google.

Sourcing Key Points: Quality control, certification, logistics, payment terms.

Pain Points: Overseas suppliers respond slowly. Hard to fix product problems quickly.

Additional Info: Understands sales, but lacks aesthetic sense.

-

Helps readers understand the function and problems associated with mezzanine connectors to provide context. ↩

1.png)